In the intricate world of cable manufacturing, cable stranding and armoring machines play pivotal roles. These machines are the backbone of creating durable, high-quality cables used in various industries, from telecommunications to power distribution. Understanding their functions, types, and technological advancements is crucial for anyone involved in cable production.

What is Cable Stranding?

Cable stranding refers to the process of twisting together two or more wires to form a single cable. This technique improves the flexibility and strength of the cable, making it suitable for various applications. Stranding can be done in different ways, leading to different types of stranded cables such as concentric, unilay, and bunch stranding.

What is Cable Armoring?

Cable armoring involves adding a protective layer to the cable to enhance its durability and resistance to physical damage. This is particularly important for cables used in harsh environments, such as underground installations or industrial settings. Armoring materials can include steel, aluminum, or copper, each offering different levels of protection.

History of Cable Stranding and Armoring Machines

The evolution of cable stranding and armoring machines dates back to the early days of cable manufacturing. Over the years, technological advancements have significantly improved these machines, making them more efficient and reliable. Key milestones include the introduction of automation, advanced control systems, and integration with modern manufacturing processes.

Components of Cable Stranding Machines

- Payoff Units: These units feed the individual wires into the stranding machine.

- Stranding Heads: These are the core components where the actual twisting of wires occurs.

- Take-up Units: These units collect the stranded cables and prepare them for the next stage of production.

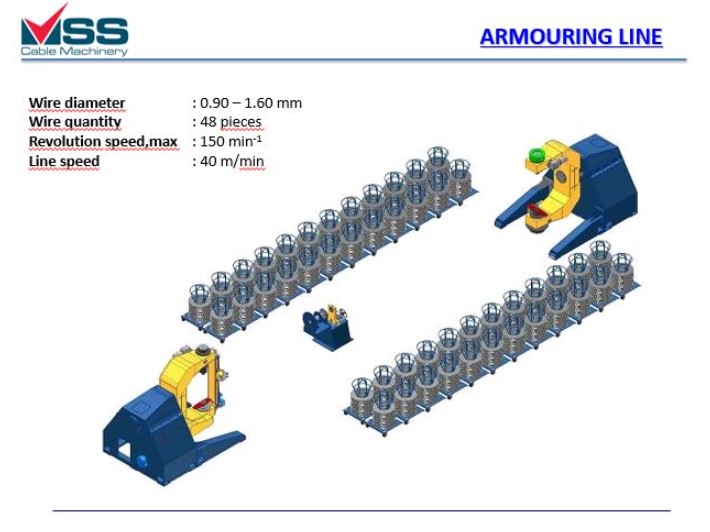

Components of Cable Armoring Machines

- Payoff Units: Similar to stranding machines, these units feed the cables into the armoring machine.

- Armoring Heads: These components apply the protective armor around the cable.

- Take-up Units: These units collect the armored cables for further processing or packaging.

Types of Cable Stranding Machines

- Single Twist Stranding Machines: These machines twist individual wires into a strand in a single operation.

- Double Twist Stranding Machines: These machines can twist multiple wires simultaneously, increasing production efficiency.

- Planetary Stranding Machines: These machines offer high precision and are used for complex cable constructions.

Types of Cable Armoring Machines

- Steel Wire Armoring Machines: These machines apply a steel layer to the cable, offering maximum protection.

- Aluminum Wire Armoring Machines: These machines provide a lightweight yet durable armor.

- Copper Wire Armoring Machines: These machines are used for applications requiring high conductivity and protection.

Technological Advancements in Stranding Machines

The advent of automation and advanced control systems has revolutionized cable stranding machines. Modern machines are equipped with sensors and software that ensure precise control over the stranding process, reducing errors and increasing efficiency.

Technological Advancements in Armoring Machines

Cable armoring machines have also seen significant improvements. Enhanced durability and protection features, coupled with integration into modern cable manufacturing processes, ensure that cables can withstand harsh conditions while maintaining performance.

Applications of Stranded Cables

- Telecommunications: Stranded cables are essential for transmitting data over long distances with minimal signal loss.

- Power Distribution: These cables are used to distribute electricity efficiently and safely.

- Automotive Industry: Stranded cables are used in vehicles for various electrical systems, providing flexibility and reliability.

Applications of Armored Cables

- Underground Installations: Armored cables protect against physical damage and moisture, making them ideal for underground use.

- Industrial Environments: These cables can withstand harsh conditions, including exposure to chemicals and extreme temperatures.

- Marine Applications: Armored cables are used in marine environments to protect against saltwater corrosion and physical damage.

Benefits of Using Advanced Stranding and Armoring Machines

- Increased Production Speed: Advanced machines can produce cables faster, meeting the growing demand.

- Improved Cable Quality: Automation ensures consistent quality, reducing defects and enhancing performance.

- Reduced Labor Costs: With automated processes, the need for manual labor decreases, lowering production costs.

Challenges in Cable Stranding and Armoring

Despite the advancements, there are challenges in cable stranding and armoring, such as high maintenance and operational costs and technological barriers that require continuous innovation and investment.

Future Trends in Cable Manufacturing

The future of cable manufacturing looks promising with trends like smart manufacturing, the use of eco-friendly materials, and the integration of Industry 4.0 technologies. These trends aim to enhance efficiency, sustainability, and overall cable performance.

Conclusion

Cable stranding and armoring machines are essential in the production of high-quality, durable cables. Continuous technological advancements and innovation are crucial to meet the evolving demands of various industries. By understanding these machines and their applications, manufacturers can optimize their processes and deliver superior products.

MSS Machinery: Crafting the Backbone of Connectivity

MSS Machinery is a global pioneer in the design and manufacture of cutting-edge cable stranding and armoring machines. With a legacy built on precision engineering and unwavering commitment to innovation, we deliver robust, efficient, and reliable solutions that power the world’s communication infrastructure.

Our machinery is the heart of the cable industry, transforming raw materials into high-performance cables that connect billions of people and devices. From the deepest oceans to the highest mountains, our machines play a critical role in enabling seamless communication and data transfer.

At MSS Machinery, we are more than just manufacturers; we are partners in progress. We work closely with our clients to understand their unique challenges and deliver tailored solutions that optimize their operations and drive their success.

Join us in shaping the future of connectivity.

MSS Machinery: Where Innovation Meets Performance.

FAQs

- What is the main function of a cable stranding machine? The main function of a cable stranding machine is to twist multiple wires together to form a single, flexible, and strong cable.

- How does cable armoring improve cable durability? Cable armoring adds a protective layer that shields the cable from physical damage, moisture, and other environmental factors, enhancing its durability.

- What industries benefit most from armored cables? Industries such as telecommunications, power distribution, automotive, and marine benefit significantly from the use of armored cables.

- Are there eco-friendly options for cable armoring? Yes, some manufacturers use eco-friendly materials and processes for cable armoring to reduce environmental impact.

-

How has automation impacted cable manufacturing? Automation has improved efficiency, precision, and consistency in cable manufacturing, reducing labor costs and increasing production speed.